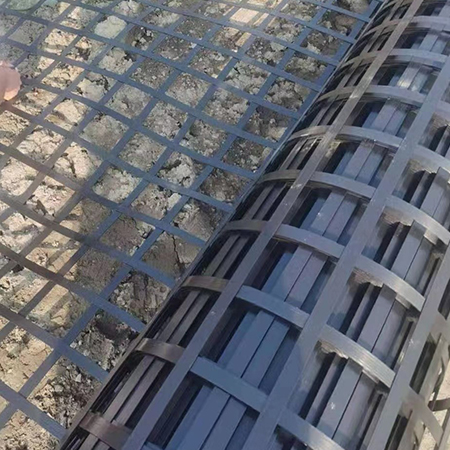

Steel plastic geogrid

2023/4/28

![]()

![]()

The high-strength steel wire woven by warp and weft can produce extremely high tensile modulus under pre stress strain, and the longitudinal and transverse ribs work together, fully exerting the locking effect of the grid on the soil; By treating the plastic surface during the production process, rough patterns are pressed and the roughness of the grid surface is enhanced, thereby improving the friction coefficient between the steel plastic grid and the soil. Resistant to acids, alkalis, and various chemical substances.

In soft foundation treatment engineering projects such as railways, highways, mining dams, thermal power plants, and landfill sites.

Reference standard JT/T925.1-2014

|

index |

Specification and model |

||||||

|

30-30 |

50-50 |

60-60 |

70-70 |

80-80 |

100-100 |

120-120 |

|

|

Longitudinal and transverse ultimate tensile strength kN/m |

≥30 |

≥50 |

≥60 |

≥70 |

≥80 |

≥100 |

≥120 |

|

Elongation under ultimate tensile strength in both longitudinal and transverse directions % |

≤3 |

||||||

|

Ultimate separation force at the connection point N |

≥300 |

≥500 |

|||||

|

index |

Specification and model |

||||||

|

50-30 |

60-30 |

80-30 |

80-50 |

100-50 |

120-50 |

180-50 |

|

|

Longitudinal ultimate tensile strength kN/m |

≥50 |

≥60 |

≥80 |

≥80 |

≥100 |

≥120 |

≥180 |

|

Transverse ultimate tensile strength kN/m |

≥30 |

≥30 |

≥30 |

≥50 |

≥50 |

≥50 |

≥50 |

|

Elongation under ultimate tensile strength in both longitudinal and transverse directions % |

≤3 |

||||||

|

Ultimate separation force at the connection point |

≥300 |

≥500 |

|||||

Anhui Chuangwan New Materials Co., Ltd. Copyright Anhui ICP Preparation No. 2023006138-1 {Disclaimers}